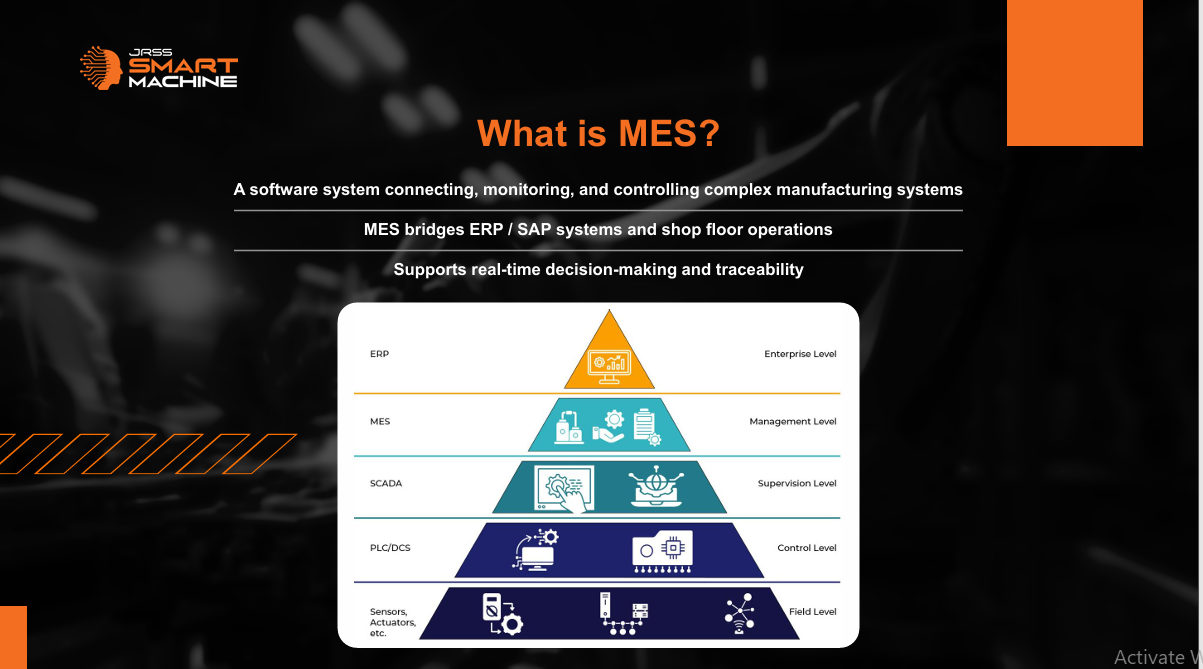

What is a Manufacturing Execution System?

A Manufacturing Execution System (MES) is a comprehensive software system that monitors, tracks, and controls the manufacturing process from raw materials to finished goods. It serves as a functional layer between enterprise resource planning (ERP) and process control systems, providing decision-makers with the data needed to make the plant floor more efficient.

MES works in real-time to enable the control of multiple elements of the production process, bridging the gap between ERP/SAP systems and shop floor operations to support real-time decision-making and traceability.

Core Capabilities of MES

Production Management

Dispatching, scheduling, and tracking of production orders.

Quality Management

Ensures products meet quality standards through real-time monitoring and control.

Performance Monitoring

Analysis of OEE and downtime to identify areas for improvement.

Inventory Control

Real-time tracking of work-in-progress (WIP) and materials.

Traceability

Lot, batch, operator, and machine-level logging for complete genealogy.

Analytics & Reporting

Generation of KPIs and dashboards for informed decision-making.

MES in Different Industries

Automotive

Real-time part tracking, ensuring quality control, and managing recalls.

Pharma

Batch compliance, traceability, and adherence to Good Manufacturing Practices (GMP).

Electronics

SMT line quality monitoring and management of complex assembly processes.

Aerospace

Spec compliance, work order tracking, and management of complex assembly processes.

FMCG

Line balancing, automation, and management of fast-moving consumer goods production.

MES in Action